Silicone PU court paving system

Classification:

Product Details

Silicone PU domestic and international authoritative certification

1. ISSS test report meeting the FIBA Level 1 venue index requirements

2. ITF court ball speed classification certification

3. China Environmental Label Product Certification (Ten Ring Type I Mark) certificate

4. Sampling inspection report from the National Sports Goods Quality Supervision and Testing Center in compliance with the national mandatory standard GB 18581-2009 for various harmful substance limit indicators

5. Provide testing report from the National Sports Goods Quality Supervision and Testing Center

6. China Green Material Mark authorized use certificate

7. Membership certificate of the China Sports Goods Industry Association

8. Recommended product by the China Middle School Sports Association Basketball Branch

9. Designated product for the CBA second venue

Performance characteristics:

1. Comfort: Whether you are running, dribbling, or standing still, the moderate stretching technology of silicone PU provides you with high comfort.

2. Vibration absorption: When silicone PU bears instantaneous impact, 63% of the impact force is absorbed by the ground system, better protecting the athlete's ankle.

3. Super abrasion resistance: The surface layer uses high-strength silicone resin particle material with a unique double-layer structure. It is more wear-resistant than ordinary products, with some having a service life of over 8 years.

4. Adhesion ability: Silicone polyurethane material can penetrate the base pores of different materials, generating high-strength adhesion for better bonding with the base.

5. Technical stability: Whether for large or small balls, the rebound, shock absorption, and friction coefficient can penetrate the entire venue system, ensuring its technical stability.

6. Ideal comprehensive function: Suitable for indoor and outdoor basketball courts, tennis courts, volleyball courts, badminton courts, handball courts, recreational venues, gyms, and other sports surfaces.

7. Easy construction: Can be directly constructed on asphalt concrete or cement concrete bases, all materials are packaged in proportionate buckets, and can be constructed according to usage instructions, making operation simple and convenient.

8. Easy maintenance: Contains anti-stain additives, stains will not penetrate the surface layer, and can be kept fresh with just water cleaning.

9. Durability:

①. Superior weather resistance: Silicone PU will not fade, harden, soften, or turn white due to outdoor high or low temperature climate changes. It can maintain its bright colors for a long time even in strong ultraviolet, ozone, rain, and high temperature difference environments.

②. Super abrasion resistance: The silicone PU surface layer uses added silicone resin particles, its structural characteristics are permanently stable, moderately soft and hard, and its wear resistance meets the needs of long-term high usage frequency.

③. Excellent stain resistance: The silicone PU surface layer is dense, moderately soft and hard. It is not easy to crack, peel, or fade, and can be kept clean and new for a long time with simple rinsing.

Performance indicators:

|

Serial number |

Inspection item |

Technical requirements |

Inspection results |

|

1 |

Breaking elongation, % |

≥400 |

1112 |

|

2 |

Tensile strength, Mpa |

≥1.8 |

3.5 |

|

3 |

Artificial climate aging resistance (300h) |

No bubbling, no peeling, no cracks; |

No bubbling, no peeling, no cracks; |

|

4 |

Abrasion resistance (750/r500r), g |

≤0.050 |

0.031 |

|

5 |

Weather resistance, aging test (168h) tensile length, % |

≥300 |

853 |

|

6 |

Weather resistance, aging test (168h) tensile strength, Mpa |

≥1.3 |

1.6 |

|

7 |

Water resistance (168h) |

No bubbling, no peeling, slight discoloration allowed, recovers after 2h |

No bubbling, no peeling, no discoloration |

|

8 |

Flame retardancy, level |

I |

|

Scope of application:

1. High-level primary and secondary schools, higher education institutions tennis courts, basketball courts, badminton courts, volleyball courts, sports fields;

2. Professional sports venues, training grounds;

3. Kindergarten playgrounds, gyms, dance studios, etc.

The requirements for the ground base of silicone PU court materials are as follows:

1. Requirements for cement ground base

1. The ground base must be laid with reinforced concrete, and the strength level must meet the standard of above secondary highway.

2. A waterproof layer must be laid before the mud is laid (depending on the specific situation on site).

3. The venue must have a complete drainage system around it, and an open channel design must be adopted.

4. The venue adopts a single-sided drainage design, and the drainage slope must reach 4-8 degrees.

5. The flatness must be measured with a 3m road ruler and the error must not exceed 3mm.

6. The surface of the ground base must be free of cracks, sand, and powder.

7. The newly constructed cement ground base must be cured for 30 days (winter time extended by 1-2 times) before the site can be paved.

8. Before paving the court, the site must be acid-washed and polished to ensure that there is no grease, oil, dust, mud, or other debris on the ground base.

II. Requirements for asphalt ground base

1. The ground base must be paved with hot-melt asphalt, and the use of emulsified asphalt is prohibited. The mixing ratio for hot-melt asphalt paving should follow the national standard for secondary highways and above.

2. A complete drainage system must be installed around the site, and an open channel design must be used.

3. The site should adopt a single-sided drainage design, with a drainage slope of 4-8 degrees.

4. The flatness must be measured with a 3-meter road ruler, with an error not exceeding 3mm.

5. The asphalt surface must not have any peeling, looseness, or cracking.

6. Newly laid asphalt must be cured for 20 days before the site can be paved.

7. Before paving the court, ensure that there is no grease, oil, dust, mud, or other debris on the ground base.

8. Only with a good foundation can a durable court surface be made.

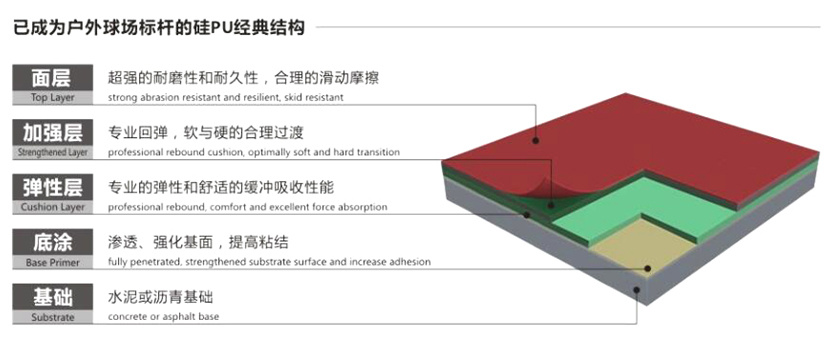

Construction process:

Base treatment → Paving elastic layer → Paving reinforcement layer → Paving wear-resistant surface layer → Marking → Site clearing and completion.

I. Base treatment

Before construction, the site should be acid-washed, polished, and filled, with a curing period of no less than 20 days.

II. Paving elastic layer

Use TB100 (solvent can be added to adjust the construction viscosity) to spread with a flat scraper or toothed scraper on the base, with each layer not exceeding 1.5mm in thickness. The time interval between each layer should be based on the previous layer's dry solidification (generally about 10 hours, depending on the weather conditions on site), until the desired thickness is achieved. [Note: After the elastic layer is dry, use the water accumulation method to test the flatness of the ground. Any accumulated water areas need to be leveled before paving the reinforcement layer.]

III. Paving reinforcement layer

Use TB200 (solvent can be added to adjust the construction viscosity) to apply in two layers about 0.8mm thick on the elastic surface, requiring a flat and smooth surface after paving.

IV. Paving wear-resistant surface layer

PB-3 should be mixed thoroughly in the ratio of A component: B component: special sand = 9:1:5, and paved on the reinforcement surface, generally in two layers. (A smooth surface can be made without adding special sand.)

V. Marking

Measure and locate according to standard dimensions, mark the line positions with a canvas line, then use masking tape along the canvas line on the court, and apply the special marking paint G008 evenly with a brush between the two masking tapes. After the material surface is dry, remove the masking tape.

VI. Site clearing and completion.

Usage precautions:

● Materials must be accurately weighed and mixed evenly during preparation.

● The surface must be kept clean before each construction process.

● Indoor sites must ensure good ventilation.

● The site must be kept for more than 5 days before it can be used.

● It is strictly prohibited to wear leather shoes, high heels, or easily discolored sports shoes on the court.

● Cutting and squeezing are strictly prohibited, and the surface should not rub against hard objects to avoid damage or cracking.

● It is strictly prohibited to use corrosive chemicals such as acids and alkalis on the floor and to keep away from fire sources and high temperatures to avoid floor deformation.

Construction maintenance period:

1. After the paving is completed, maintenance is required for 10-15 days until the ground material is completely dry before it can be used.

2. During the construction maintenance period, personnel movement, trampling, and wear are prohibited.

3. During the construction maintenance period, prevent long-term water accumulation and dampness.

4. If blisters, cracks, or other issues occur during the maintenance period, they should be promptly repaired by professional construction personnel.

5. If the weather is persistently overcast, humid, or in winter, the maintenance period should be appropriately extended.

6. After the maintenance period, due to the new properties of the material, it can effectively resist water, UV rays, and wear.

Usage maintenance:

1. The plastic court can be used in all weather conditions if equipped with certain drainage facilities.

2. The plastic court is only for athletes' training, competitions, and exercise, and should not be used for other purposes.

3. Athletes must wear specialized sports shoes; if the shoes have spikes or heels, they are not allowed on the plastic court.

4. Regular maintenance and inspections should be conducted. Damaged or loose areas should be repaired promptly, and waste such as garbage, glass, leaves, etc., should be removed.

5. The edges of the plastic court should be protected and not moved arbitrarily. If damage or bubbling is found, it should be repaired immediately.

6. Vehicles are not allowed on the court, nor should heavy objects or sharp items be placed on it.

7. Avoid contact with organic solvents, chemicals, cigarette butts, and other sources of fire and pollutants.

8. Keep clean; it can be rinsed with water, and any residual water on the rubber surface can be removed with a dry cloth. Oil stains can be cleaned with 10% ammonia or detergent.

9. It is strictly prohibited to spit out chewing gum and oil pollution to prevent the court from being uncleanable.

10. When clearing snow, be sure to use a broom to sweep, and if necessary, the lines and signs should be updated.

Key words:

Ball Game Venue Series

Previous Page

Next Page

Online Consultation

Note: Please leave your email address, our professionals will contact you as soon as possible!