Water-based flat coating

Classification:

Product Details

Performance Characteristics

1. Strong coverage, good wear resistance, dustproof, moldproof, moisture-proof, and acid-alkali resistant.

2. Strong adhesion, good flexibility, easy to clean and maintain.

3. Thin coating type, seamless, beautiful appearance, various colors, with good decorative and practical properties.

4. Easy construction, economical flooring. Thickness about 0.3~0.5mm, service life 3-5 years.

Applicable Scope

Coating of cement floors in various places such as electronics, electrical appliances, food, feed, tobacco, textiles, clothing, pharmaceuticals, chemicals, communication equipment, instruments, parking lots, exhibition halls, light industry, etc.

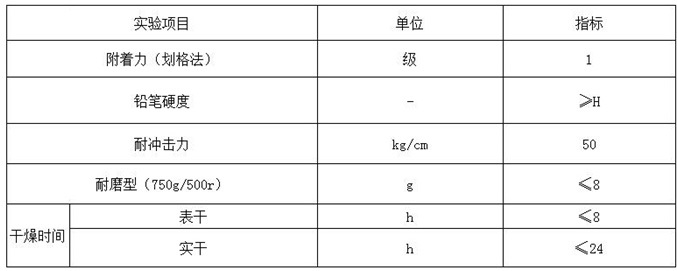

Main Performance:

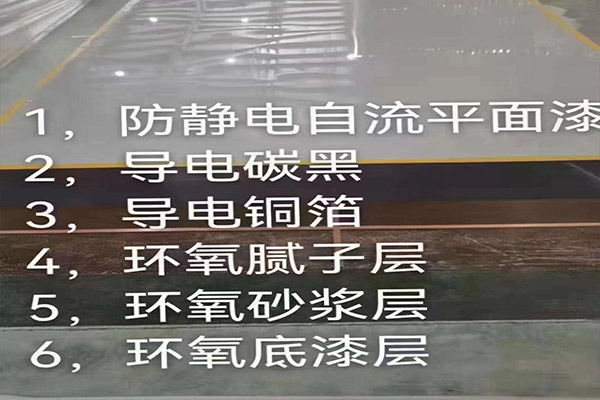

Construction Procedures and Main Materials:

| Test Items | Construction Method | Main Materials | Auxiliary Materials |

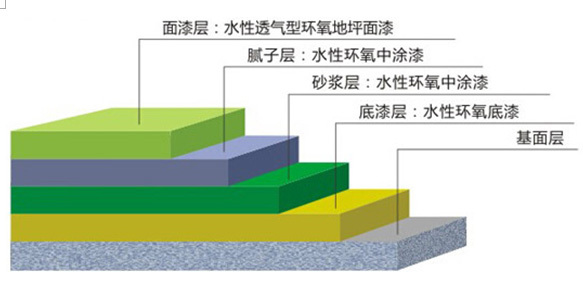

| Base Surface Treatment | Polish the base surface, repair defects, clean and dry. | - | - |

| Primer Layer | Roll on epoxy primer. | Water-based epoxy primer. | - |

| Mortar Layer | Mix quartz sand with epoxy intermediate material to the required thickness. | Water-based epoxy intermediate paint. | Quartz powder. |

| Putty Layer | Use epoxy intermediate material to mix quartz powder for putty layer. | Water-based epoxy intermediate paint. | Quartz powder, double-fly powder. |

| Topcoat Layer | Spray or roll on one coat of water-based odorless colored flat paint. | Water-based epoxy floor paint. | - |

Cross-section display:

Construction Precautions:

1. Please ensure good ventilation at the construction site.

2. No smoking or open flames during construction.

3. Clean any contaminated areas during construction, and remove all site waste after construction.

4. Dust on the ground must be completely removed to ensure the adhesion effect of the primer.

5. The ground must be cement polished, with a strength of 3000 PSI (or 210 kg/cm2, C-25) or above, and the surface must be hard, flat, without delamination or sand rising, and water treatment must be done.

6. If the ground is damp, it must be dried, with a moisture content below 8%, or use special primer.

7. If the epoxy resin coating layers exceed the effective adhesive time, roughen and clean the surface of the material, apply a layer of primer (depending on the time interval), and then proceed with the next layer of coating.

8. Since the primer contains solvents, construction can only proceed after complete evaporation to avoid bubbling.

9. For damp areas, first dry with a gas torch (lighter) or sun lamp, then apply primer or use special primer first.

10. When materials are stored outdoors, they should be neatly stacked on pallets and covered with PVC tape to prevent water ingress.

11. Materials mixed after stirring should be applied within the usable time to avoid the surface approaching hardening and being unable to level.

Key words:

Water-based Epoxy Flooring Material System

Previous Page

Next Page

Online Consultation

Note: Please leave your email address, our professionals will contact you as soon as possible!